Geef feedback

over ons

Het bedrijf is al jarenlang toegewijd aan productinnovatie, met de focus op de update en upgrade van pneumatische motoren. Met uitstekende ideeën en voortdurende investeringen heeft het een creatief ontwerpteam opgebouwd en veel innovatieve pneumatische producten ontworpen. Het heeft momenteel onafhankelijke kennis Intellectueel eigendom rechten en heeft meer dan 30 productpatenten verkregen.

De belangrijkste producten van het bedrijf zijn pneumatische motoren en een reeks producten zoals pneumatische takels, pneumatische lieren, pneumatische mengers, pneumatische emulgatoren, pneumatische explosieveilige pompen, pneumatische mengers, pneumatische ventilatoren en industriële automatiseringsapparatuur. Pneumatische besturingssystemen worden ontwikkeld op basis van specifieke productiebehoeften.

Het bedrijf volgt strikt het ISO9001-kwaliteitsmanagementsysteem voor productontwerp, productie, assemblage en testen. Met de inspanningen van alle werknemers heeft het bedrijf de ISO9001-certificering voor het internationale kwaliteitssysteem behaald. Door middel van strikte procedures en hoogwaardige audits heeft het bedrijf met succes heeft het certificaat "National High-tech Enterprise" behaald. Gaston beweegt zich geleidelijk in de richting van internationalisering, met eigen kracht en een wereldwijde visie.

Gebruikers met verschillende behoeften zullen altijd de coördinaten van onze strijd zijn en de drijvende kracht om onszelf voortdurend te overtreffen en te streven naar innovatie! Gaston kijkt uit naar een oprechte samenwerking met vrienden uit alle lagen van de bevolking, zowel in binnen- als buitenland, om samen iets geweldigs te creëren!

Duurzaamheid waarop u kunt vertrouwen

Precisie en efficiëntie

Wij gebruiken Zwitserse CNC-machines in plaats van conventionele bewerkingsmachines.

Zwitserse CNC-machines combineren deze functies in één werkplaats: draaien, frezen, boren, etc.

Voordelen:

·Hoge precisie

·Hoge efficiëntie

·Verminder processtappen tot een minimum

·Arbeidskosten verlagen

Kwaliteitscontrole

Compleet testlaboratorium

We hebben systemen voor gereedschapslevensduurcontrole en slijtagecompensatie, coördinatenmeetmachines (CMM s) en andere precisietestapparatuur geïntroduceerd om de maatnauwkeurigheid, oppervlaktekwaliteit, dynamische prestaties en andere belangrijke indicatoren van pneumatische apparatuur uitgebreid te testen om ervoor te zorgen dat elk apparaat aan de strenge kwaliteitseisen kan voldoen. vereisten.

Certificaat van eer

Laatste nieuws

-

Industrie nieuws 2025-09-08

In moderne industriële productiesystemen bepaalt de prestaties van stroomeenheden direct de effic...

Bekijk meer -

Industrie nieuws 2025-09-01

In de moderne industrie heeft de keuze van energietransmissieapparatuur direct invloed op de prod...

Bekijk meer -

Industrie nieuws 2025-08-22

In de enorme arena van de Moderne Industrie Productie tilt apparatuur op een onmisbare 'Held...

Bekijk meer -

Industrie nieuws 2025-08-15

In de Moderne Industrielle Productie is Mengapparaturur een Kerncomponent van MaterialbeHandeling...

Bekijk meer -

Industrie nieuws 2025-08-08

In complexe vloeistoftransportscenario's in de industrie productie, Roostvrijstalen Pneu...

Bekijk meer

Neem nu contact met ons op

Pneumatische reductiemotor Kennis van de industrie

How to lead the new era of pneumatic reduction motors with diversified reducer configurations?

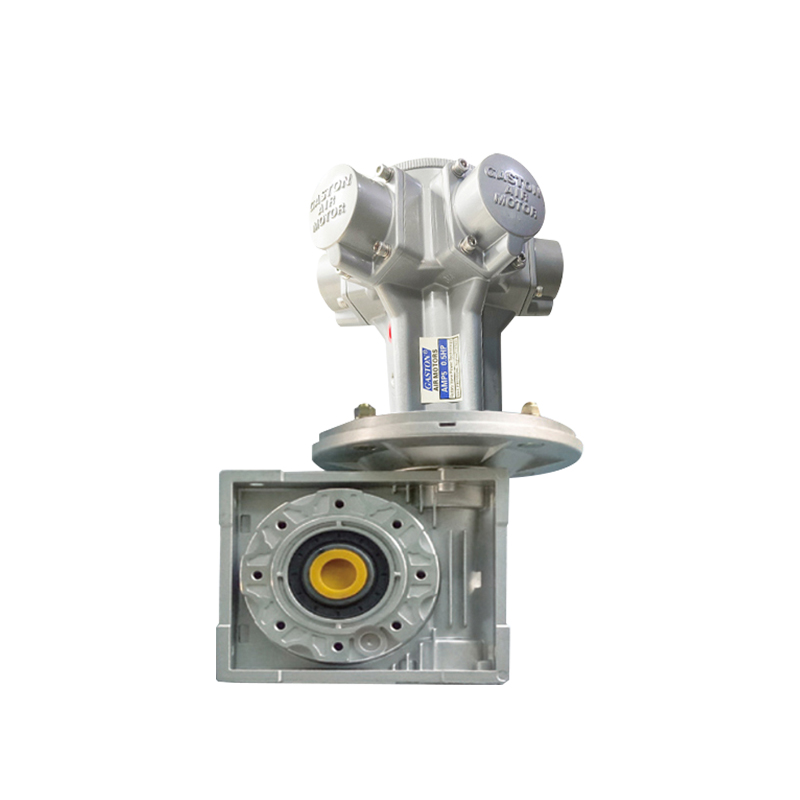

Today, as automation and intelligence are becoming the mainstream trends in industrial production, the performance and customization capabilities of pneumatic reduction motors, as core components in the field of power transmission and control, are directly related to the efficiency and stability of the entire production line. Anhui Gaston Precision Machinery Co., Ltd., as a company in domestic pneumatic motor and equipment manufacturing, not only focuses on the entire chain of design, research and development, production, sales, and service, but also demonstrates extraordinary innovation and market adaptability in the field of pneumatic reduction motors. This article will explore in depth how the company brings more efficient and accurate pneumatic reduction motor solutions to the market through diversified reducer configurations, and raises several thought-provoking questions.

1.Diversified reducer configuration: meeting the needs of different working conditions

One of the core competitiveness of Anhui Gaston Precision Machinery Co., Ltd.'s pneumatic reduction motors lies in its rich selection of reducers. From the AMP-C series helical gear reducers to the AMP-R series, AMP-RV series, and AMP-P series planetary reducers, each type is optimized for specific application scenarios to ensure efficient operation under different loads, speeds and working environments. For example, the AMP-C series is widely used in heavy machinery and equipment with its high torque and low noise characteristics; while the AMP-P series planetary reducer has become the first choice in the field of precision control with its compact structure and large transmission ratio.

2.Customized service: flexible assembly of FB type brake (air brake)

In addition to the diverse reducer configurations, Anhui Gaston also provides flexible assembly services for FB type brake (air brake). Pneumatic reduction motors manufacturer not only enhances the braking performance of the pneumatic reduction motor, but also makes the equipment faster and more accurate during emergency shutdown or positioning control, further improving the safety and stability of the production line. This customer-centric service concept of providing customized solutions is the key to Anhui Gaston's ability to stand out in the fiercely competitive market.

3. Question discussion: How to accurately select and configure?

1) When faced with a variety of pneumatic reduction motor products, how should companies quickly locate the products that best suit their needs?

Answer: The key is to clarify the specific needs of the application scenario, including load size, operating speed, working environment (such as temperature, humidity, corrosiveness), space restrictions, etc. At the same time, the convenience of equipment maintenance, cost-effectiveness and long-term operation stability must also be considered.

2) How does Anhui Gaston's customized service help companies solve special needs problems?

Answer: Anhui Gaston communicates with customers in depth to understand their specific needs and challenges, and provides a full range of customized services from product design to production and manufacturing. This includes but is not limited to adjusting the reduction ratio, selecting special materials, integrating specific functions (such as air brakes), etc., to ensure that the product perfectly matches customer needs and improves the overall performance of the equipment.

3) In the daily maintenance of pneumatic reduction motors, what key points should be paid attention to?

Answer: The key points of daily maintenance include regularly checking the oil level and oil quality to ensure the normal operation of the lubrication system; cleaning the transmission parts to prevent the accumulation of impurities that affect the transmission efficiency; paying attention to the quality of the air source to prevent moisture and impurities from entering the pneumatic system; and regularly checking the tightness of fasteners to prevent failures caused by looseness.

Anhui Gaston Precision Machinery Co., Ltd. is constantly promoting the progress and development of the pneumatic reduction motor industry through its strong technical strength, rich product lines and flexible customized services. Facing the future, we have reason to believe that this company will continue to lead the new trend in the field of pneumatic reduction motors with its products and services.